You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Autech Pulsar GTi

- Thread starter Dale

- Start date

Interesting setup and mad hard work, straight away I think heat soak........

Its a good point Dave. The intake tube will get quite warm, theres no escaping that.

However, since the filter is drawing in cold air, i feel that the air will be consumed by the engine before it has chance to heat up any significant amount.

I am doing what i can to manage heat, there is a shield above the exhaust manifold and a heat shield to come for the air filter itself.

However, since the filter is drawing in cold air, i feel that the air will be consumed by the engine before it has chance to heat up any significant amount.

I am doing what i can to manage heat, there is a shield above the exhaust manifold and a heat shield to come for the air filter itself.

Heatwrap it then reflective foil on it

Sent from my GT-I9505 using Tapatalk

Sent from my GT-I9505 using Tapatalk

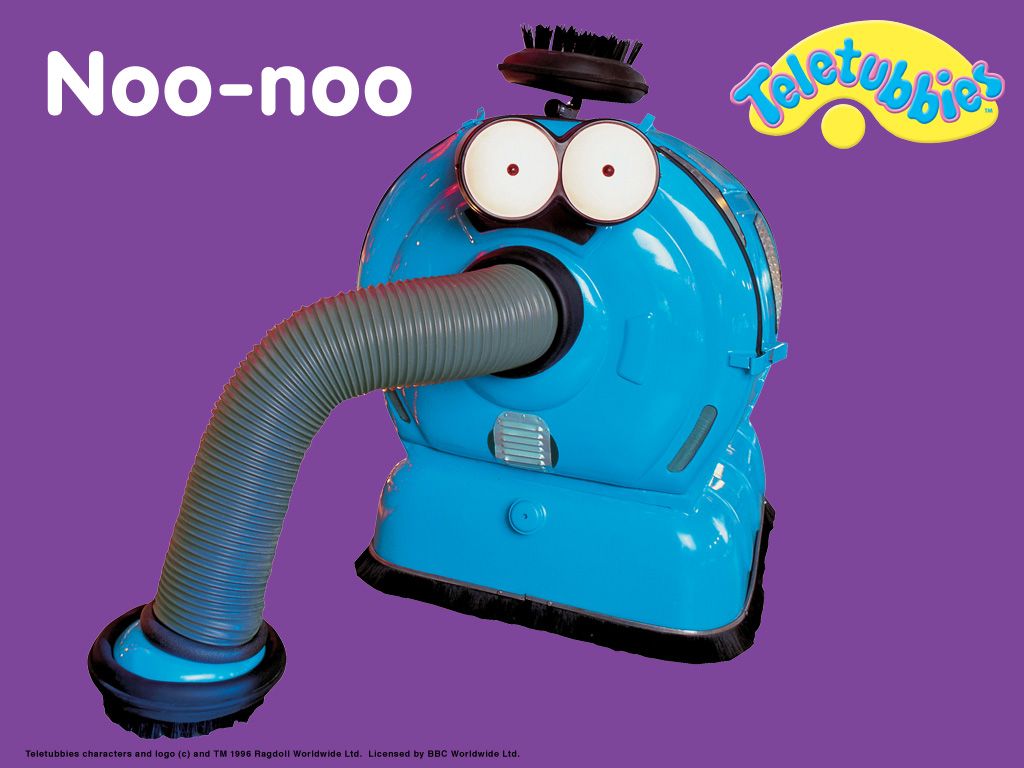

Good work Dale. It brought to mind the F2 intake with the 100mm flexi tubing into cold air box:

I think you'd be better putting a 90° bend at the plenum and then having the throttle facing the inner wing, not unlike the pic above really. You may be able to fit a 90° silicone bend on it and then route round the side though. Still got those ITB's for sale?

I think you'd be better putting a 90° bend at the plenum and then having the throttle facing the inner wing, not unlike the pic above really. You may be able to fit a 90° silicone bend on it and then route round the side though. Still got those ITB's for sale?

A 90 deg bend right at the throttlebody would be a turbulent restriction though wouldnt it? A regular side feed plenum would be ok though.

The idea of a centre feed intake in my head is similar to ITB's, delivering EVEN flow to each cylinder.

On our side feed plenums, No4 cylinder will typically recieve less flow. You could compensate for this if you are tuning cylinders individually, but normally otherwise we are compromising the engine tune, having no4 running richer than the other cylinders

Somebody has already tried a very similar setup to mine on a 2ltr VE, but he had a 90 deg elbow straight after the throttle body. He made 165ftlb and gained 15ftlb of torque over an xcessive N1 plenum setup. It did however loose HP after 7600rpm, probably because of that 90deg elbow!

I still have these roller ITB's yeah.

The idea of a centre feed intake in my head is similar to ITB's, delivering EVEN flow to each cylinder.

On our side feed plenums, No4 cylinder will typically recieve less flow. You could compensate for this if you are tuning cylinders individually, but normally otherwise we are compromising the engine tune, having no4 running richer than the other cylinders

Somebody has already tried a very similar setup to mine on a 2ltr VE, but he had a 90 deg elbow straight after the throttle body. He made 165ftlb and gained 15ftlb of torque over an xcessive N1 plenum setup. It did however loose HP after 7600rpm, probably because of that 90deg elbow!

I still have these roller ITB's yeah.

Last edited:

A 90 deg bend right at the throttlebody would be a turbulent restriction though wouldnt it? A regular side feed plenum would be ok though.

The idea of a centre feed intake in my head is similar to ITB's, delivering EVEN flow to each cylinder.

On our side feed plenums, No4 cylinder will typically recieve less flow. You could compensate for this if you are tuning cylinders individually, but normally otherwise we are compromising the engine tune, having no4 running richer than the other cylinders

Somebody has already tried a very similar setup to mine on a 2ltr VE, but he had a 90 deg elbow straight after the throttle body. He made 165ftlb and gained 15ftlb of torque over an xcessive N1 plenum setup. It did however loose HP after 7600rpm, probably because of that 90deg elbow!

I still have these roller ITB's yeah.

Side inlet manifolds are not ideal I agree. The Subaru Impreza has trouble with intake flow at the rear two cylinders which can cause them to detonate and destroy the engine. Common fault apparently. The side inlet plenums usually taper toward the last cylinder to increase pressure at that point in an attempt to even out the poor, uneven flow characteristics that are incumbent with that design.

I don't think an even mandrel bend would cause much restriction at all. Turbulence is a blessing anyway with induction, up to a point, provided the intake velocity isn't affected. Turbulant air entering the plenum will fill it much more evenly than a more laminar flow. It's better for fuel mixture too as it mixes the air and fuel more evenly. The current thinking puts turbulant flow in such high regard that speed shops are making dimples in the intake ports to create more than would naturally occur.

You'll not be getting anywhere near a nice flow through that induction tubing anyway, at least not as much as trough a smooth bore pipe.

Just my opinion obviously but you've done a lot more with regards proper nuts and bolts tuning than me so I take your point.

Must sound RaceCar at WOT D?